Our Business

Our Business

Home > Our Business > Protecting Nature and the Beautiful Surroundings

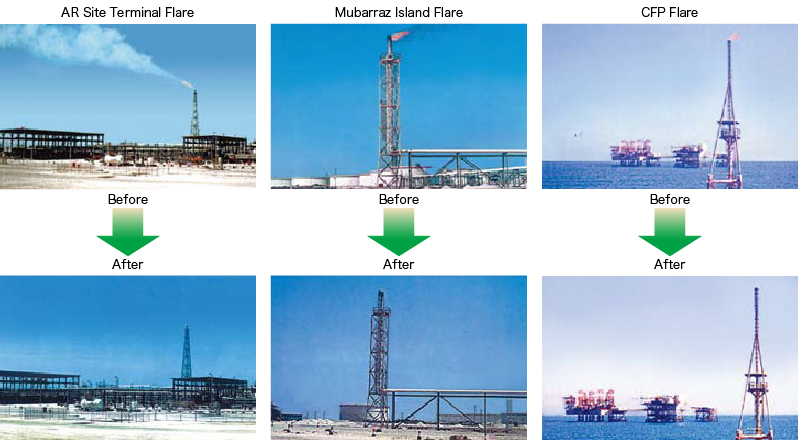

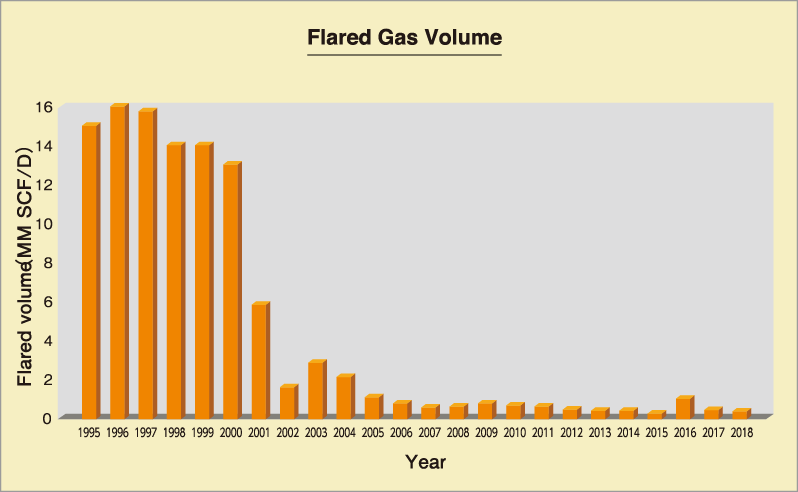

Flames from a flare stack were in the past a common sight in the oil fields. These flames originate from the gas associated with crude oil, and gases liberated in the crude oil treatment process are disposed of by flaring. These gases sometimes contain toxic hydrogen sulfide and carbon dioxide, and are referred to as “ sour gases”. The flaring of sour gases not only means that natural gas resources are being wasted, it also results in the release into the atmosphere of a large amount of pollutants, as sulfur dioxide has an adverse effect on the environment and carbon dioxide is a major contributor to global warming.

Flames from a flare stack were in the past a common sight in the oil fields. These flames originate from the gas associated with crude oil, and gases liberated in the crude oil treatment process are disposed of by flaring. These gases sometimes contain toxic hydrogen sulfide and carbon dioxide, and are referred to as “ sour gases”. The flaring of sour gases not only means that natural gas resources are being wasted, it also results in the release into the atmosphere of a large amount of pollutants, as sulfur dioxide has an adverse effect on the environment and carbon dioxide is a major contributor to global warming.

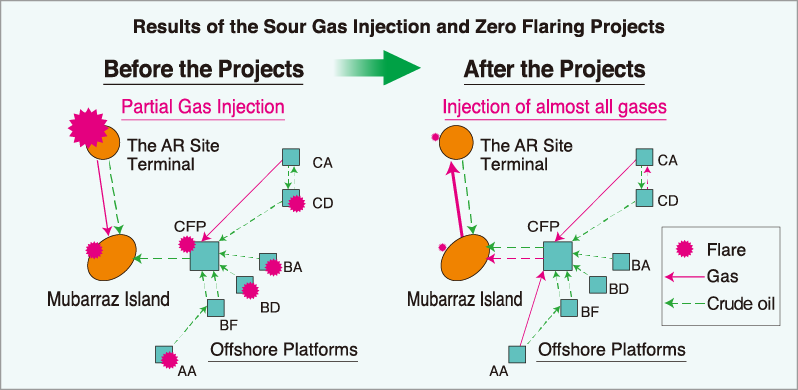

Recognizing the importance of both protecting the environment and conserving resources, we have completed a Sour Gas Injection Project (SGIP) in which sour gas is injected into oil reservoirs and the amount of gas injected is increased. This enables us to simultaneously protect the environment, conserve resources and enhance oil recovery. As a direct result of the SGIP, we have minimized flaring and now all of the sour gas is injected into the oil reservoirs.

After initiating the SGIP, we set to work on the Zero Flaring Project (ZFP) in order to further promote environmental protection. Until this project began, both gas associated with crude oil in Mubarraz Field and gas liberated in the processing facilities on Mubarraz Island had been flared. The ZFP was intended to recover these gases and transport them to the AR Site Terminal, thereby minimizing gas flaring. As a result of this project, we have achieved zero gas flaring in the Mubarraz Field and have minimized the amount of gas flared on Mubarraz Island. In addition, we have implemented other measures designed to further reduce the amount of gas flaring, which includes the adoption of a tank gas recovery process and the installation of additional gas sweetening units on Mubarraz Island. At present, we are working to optimize the gas processing through a series of measures in order to avoid flaring during maintenance or special operations. We are therefore consistent in our efforts to meet the challenge of achieving zero flaring.

Water produced from wells and discharged from the processing facilities must be disposed of in a safe manner. In order to achieve this, we have implemented a “Water Disposal Project” in which we have realized zero release of waste water into the environment. After removing oil from formation water and processing waste water, it is injected into an underground formation through a water disposal well located adjacent to the new jetty at Mubarraz Island.

On Mubarraz Island, a desalination plant converts seawater into fresh water which is then delivered to the employees' accommodation and to the crude oil processing facilities. On a very hot and isolated island, fresh water is valuable not only for humans but for plants as well. We continue to vigorously work on irrigating plants, planting trees and afforestation of the island using treated waste water. What was once a desert island is now covered with mature trees swaying in the wind. These trees play an important role in improving both industrial hygiene and the working environment. In addition to planting trees on the island, since 1983 we have actively been planting mangroves that grow in the seawater surrounding the island. The mangrove plantation has further accelerated through mangrove campaigns since 2005, which has improved the environment for small creatures such as shrimps and crabs. Some mangroves have grown to a height of more than four meters, providing places of rest and relaxation for employees. The island is now also an oasis for numerous migratory birds.